2014 - 2015

Opentrons Platform Prototype

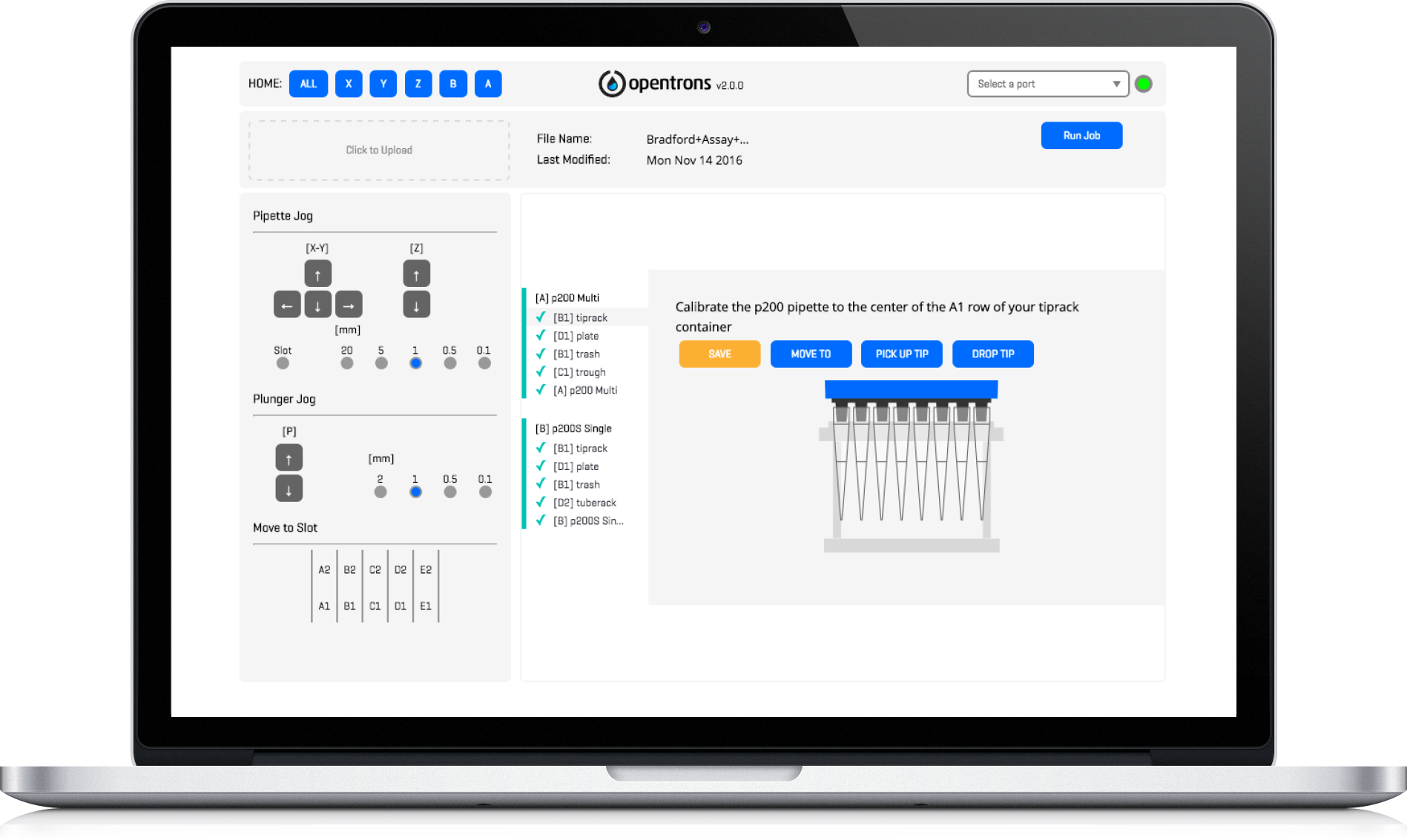

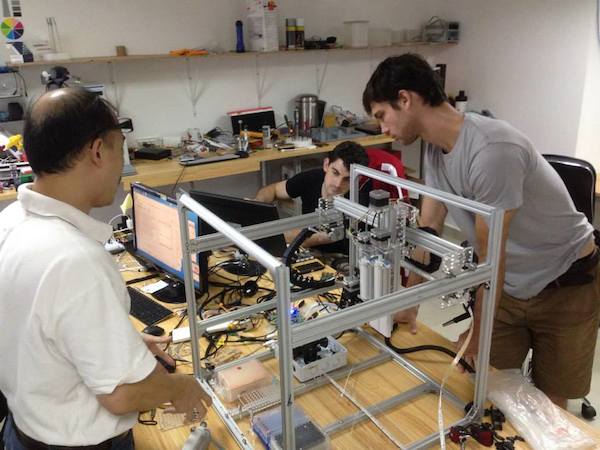

I worked with Opentrons to build a prototype of their liquid-handling platform’s software stack.

Below is a quick video from 2015, demonstrating the prototype. All designs and software in the video (excluding the motor controller) were made by me.

The commands were based on the Auto-Protocol standard proposed by Transcriptics, and the system was written in NodeJS and HTML5.

PROJECTS

automation