OT2 Liquid Handler Electronics

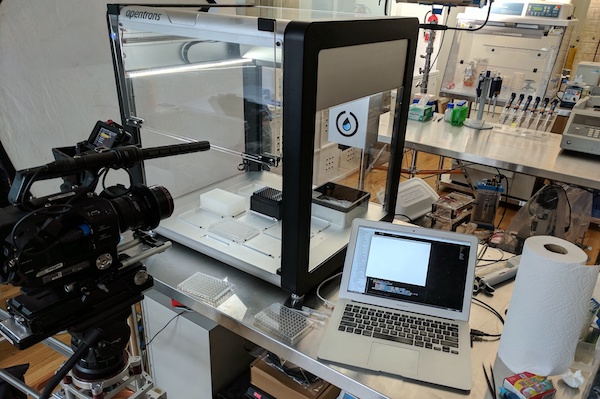

The Opentrons OT2 liquid handler is the 2nd generation liquid handler from Opentrons.

I had the privelege of owning the planning, development, and implementation of all electronics in the machine, as well as leading firmware and motion-control systems.

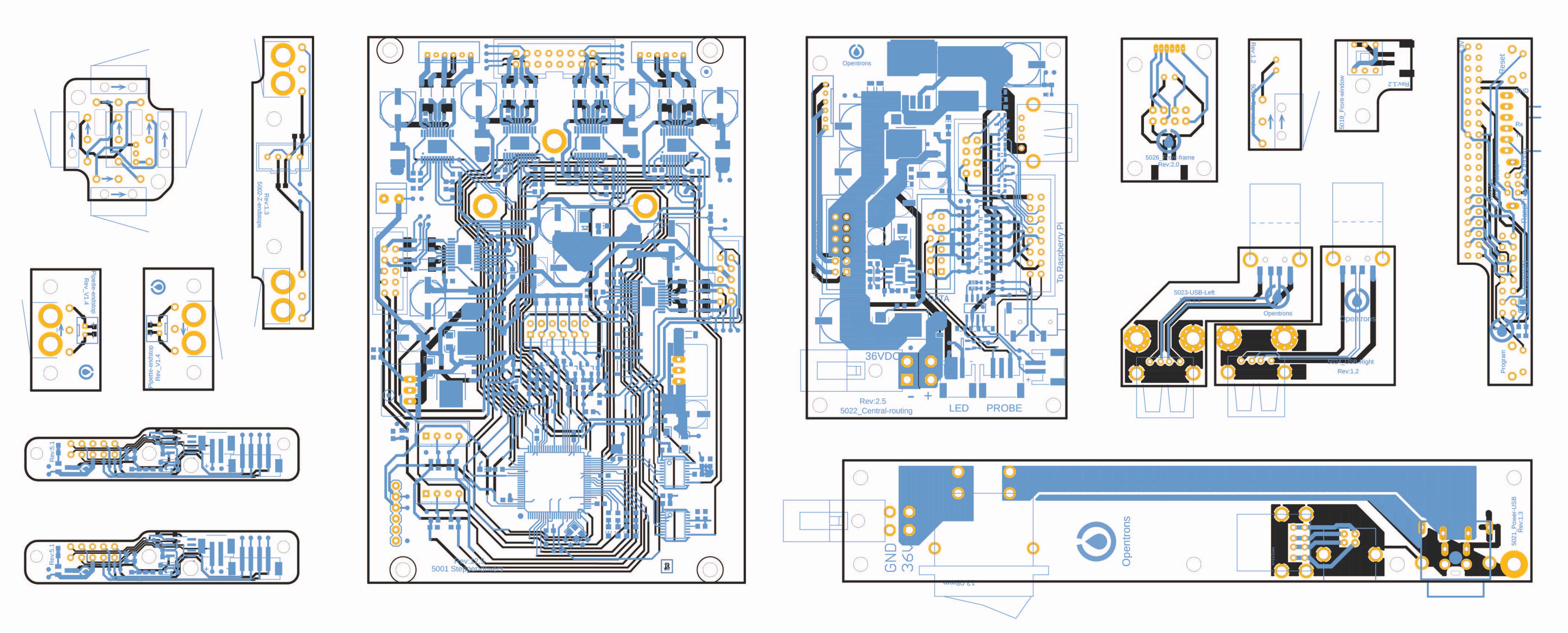

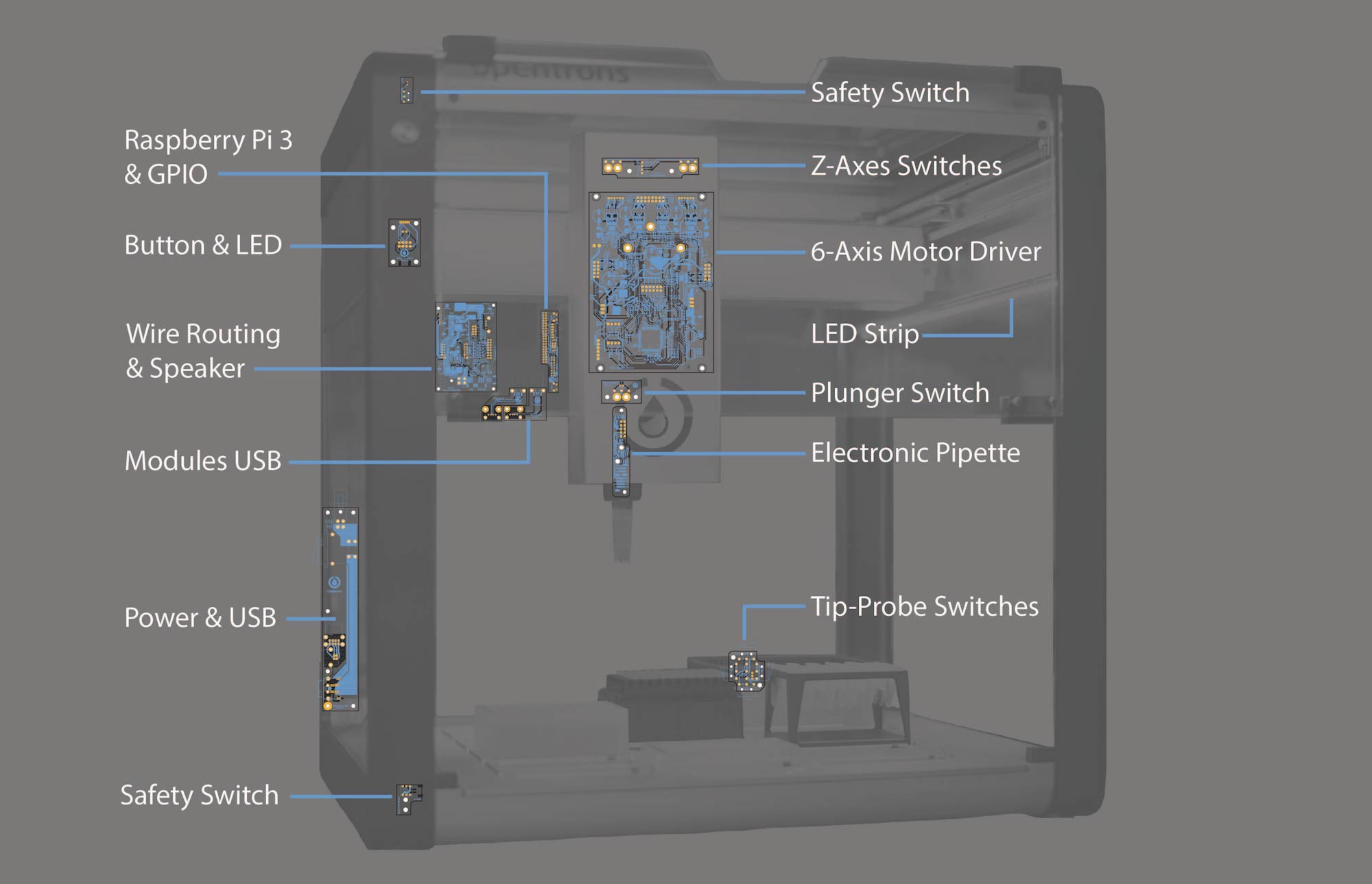

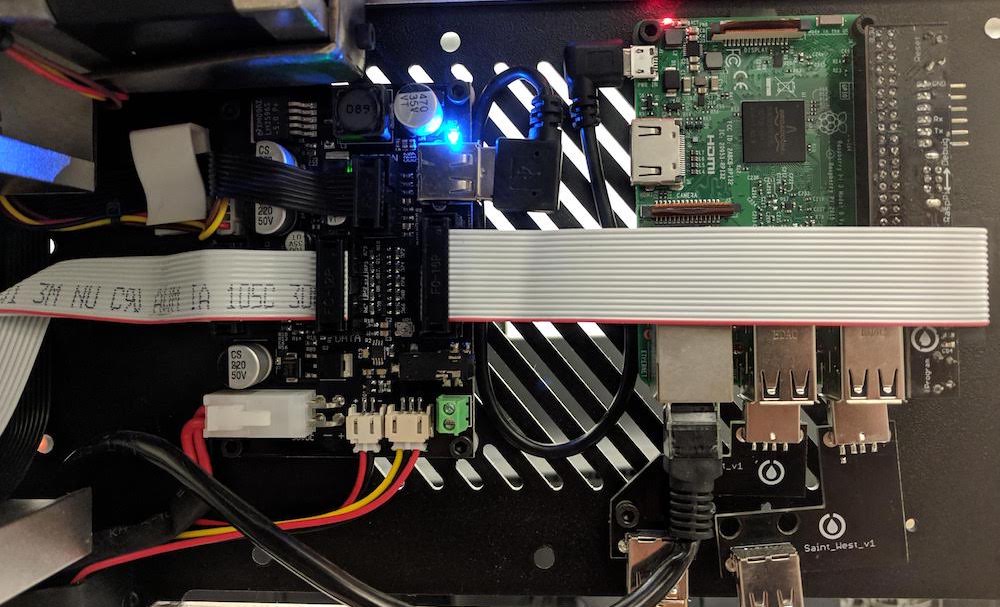

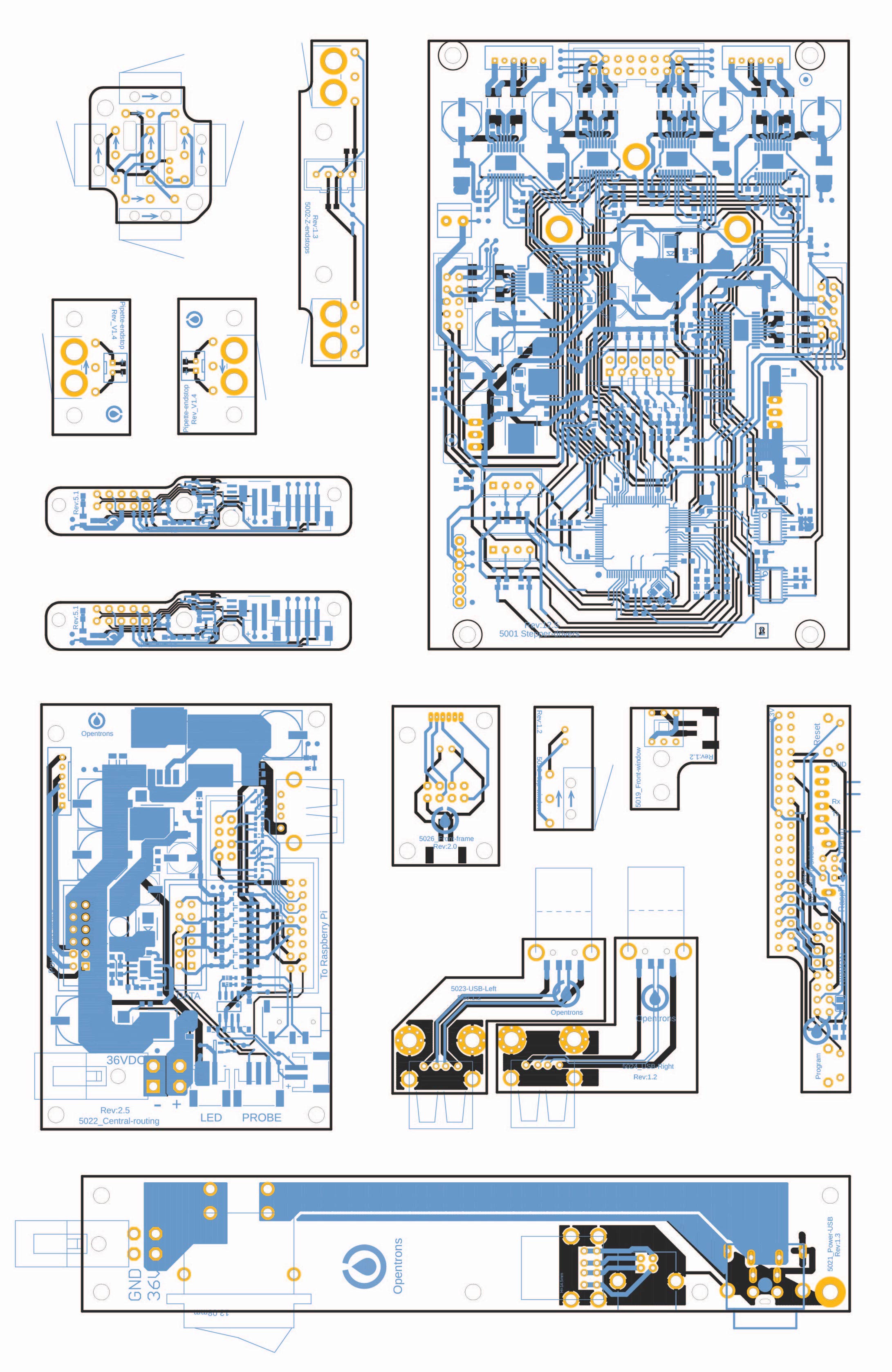

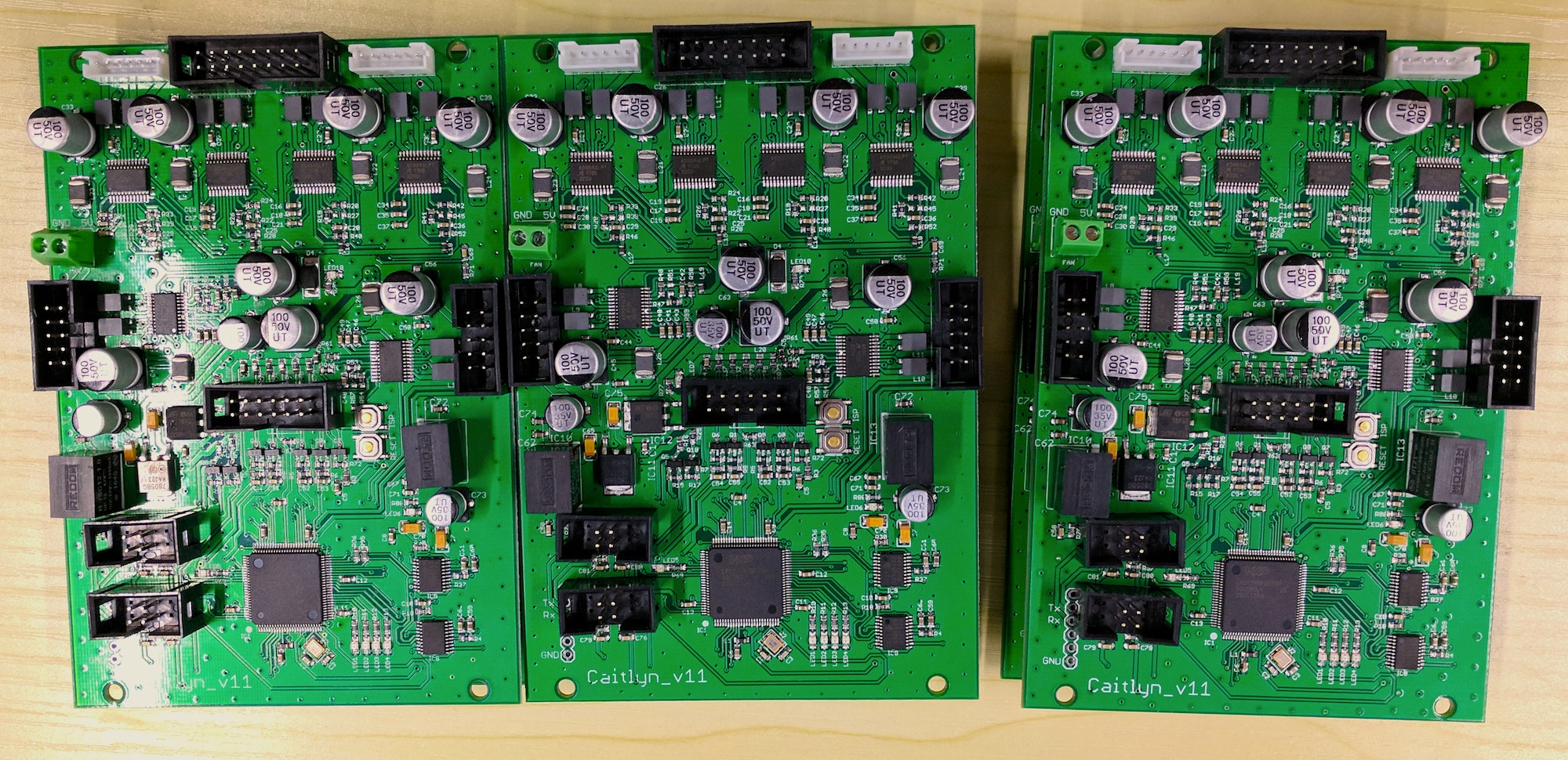

Circuit Boards

The OT2 has 13 circuit boards inside it (plus a Raspberry Pi 3 and USB camera):

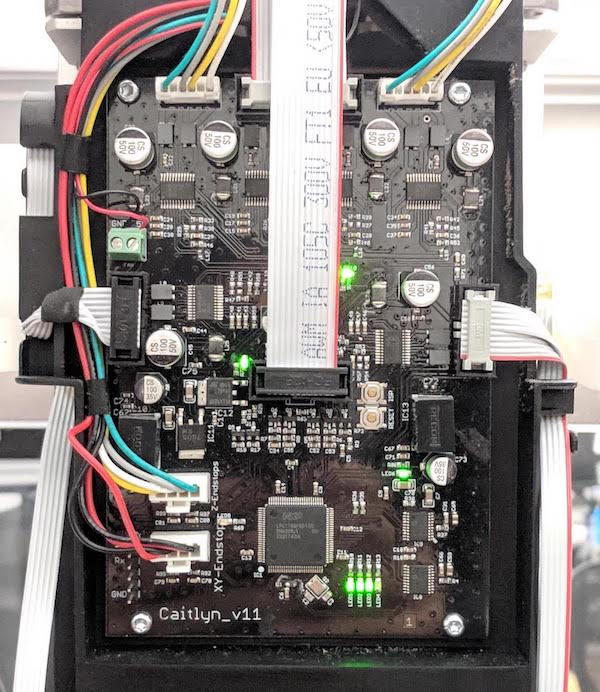

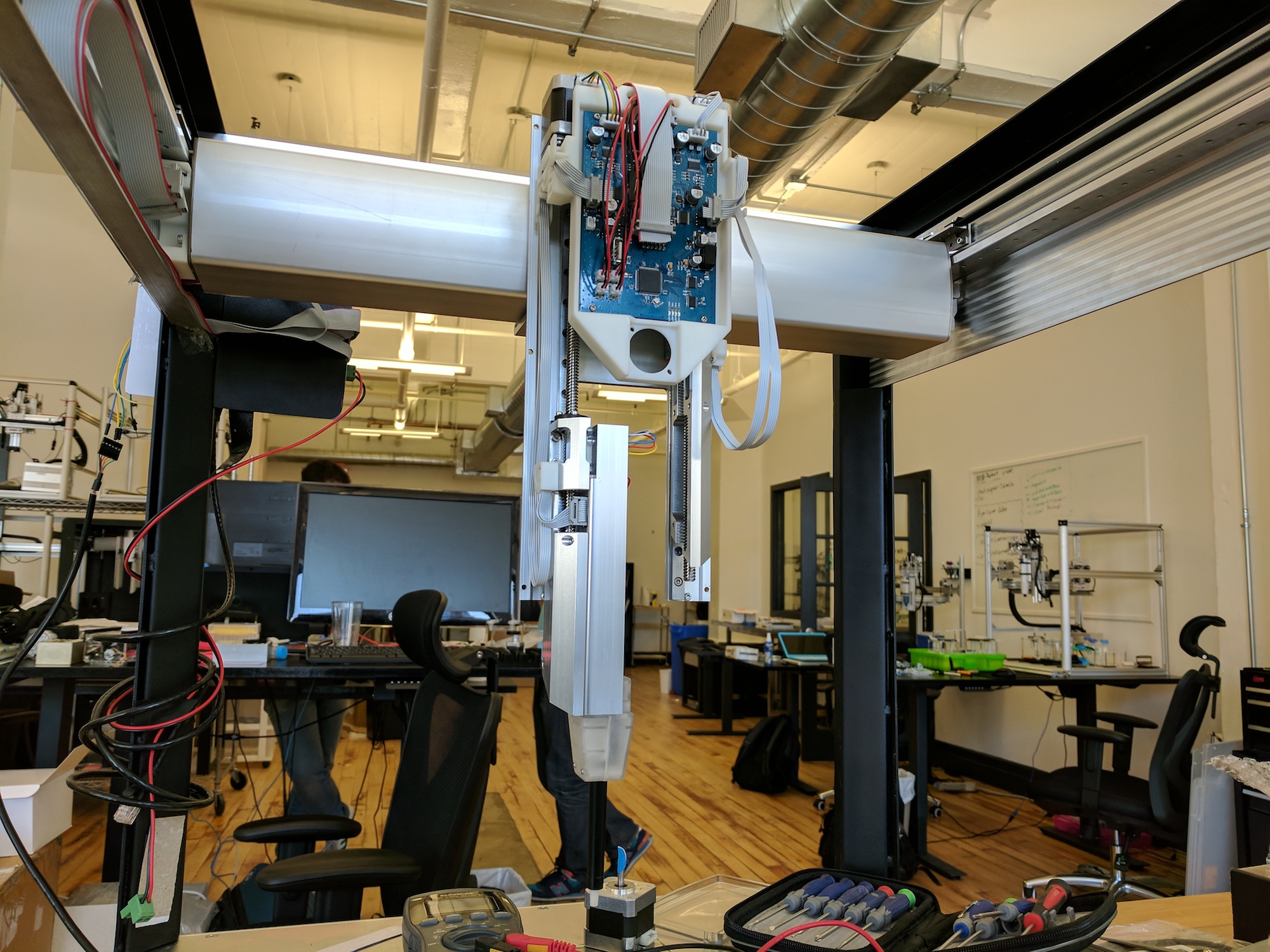

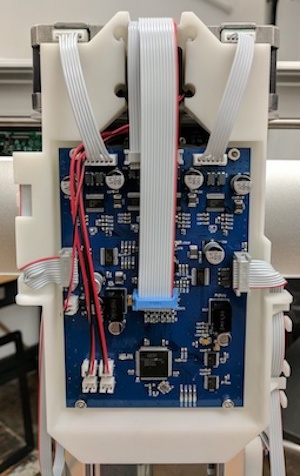

The motor-driver PCB is in the machine’s head. It can control 6 stepper motors, and runs on a fork of the open-source Smoothieware firwmare.

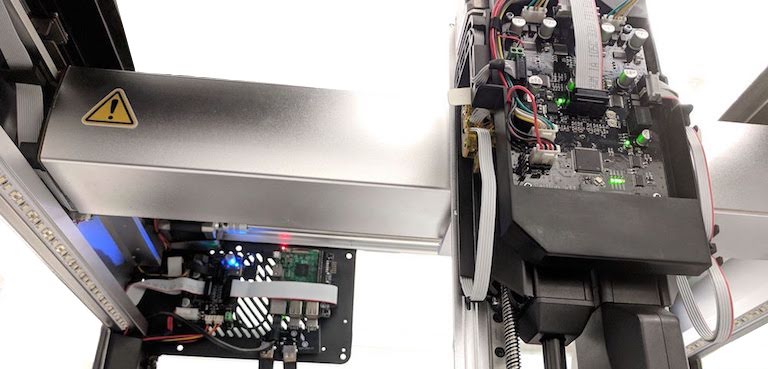

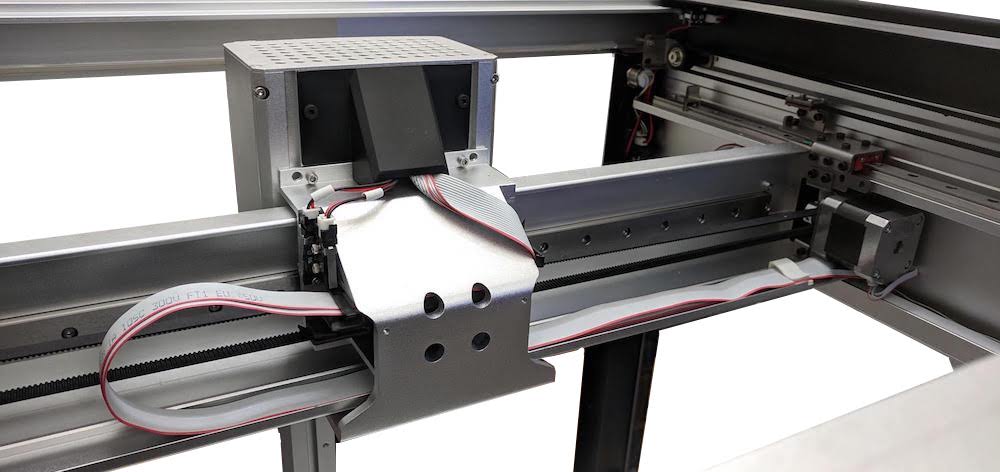

Flex Ribbon Cable

A 2-meter-long ribbon cable is used to route 32 conductors (power, data, and motor signals):

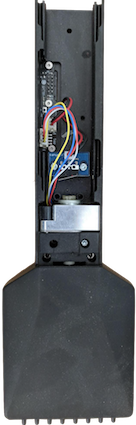

Electronic Pipettes

The OT2 electronic pipettes use a fairly simple mechanism to move the plunger up and down. The pipette’s stepper motor is being driven by the main driver PCB, so no motor driver was required inside the pipette. The electronics inside the pipette also store the unique serial and model numbers.

Tip Probe

The tip-probe is a series of 5 switches, used to detect the precise and accurate position of a disposable tip on a pipette.

The tip-probe allows the OT2 to calculate the position, height, and diameter of a pipette tip.

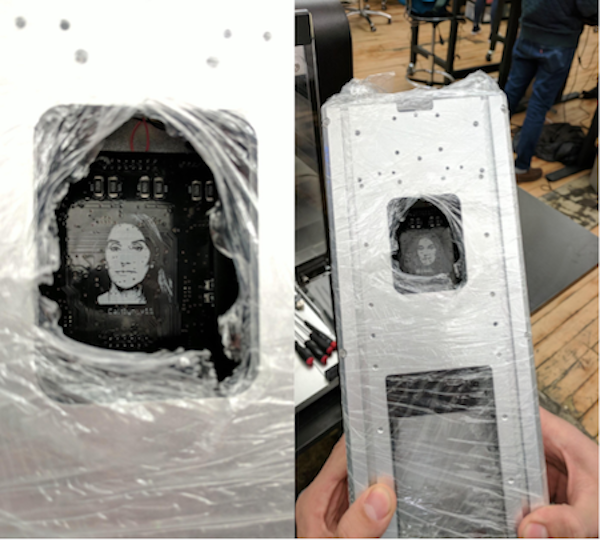

More PCB Artwork

Some Pictures from Before & After Launch

PRODUCTS

opentrons pcb opensource