Opentrons Modules

During 2017-‘18, I was the sole electronics designer and firmware developer for three Opentrons Modules:

- Thermocycler Module

- Temperature Module

- Magnetic Module.

These devices connect to the Opentrons OT2 hardware platform to automate lab protocols.

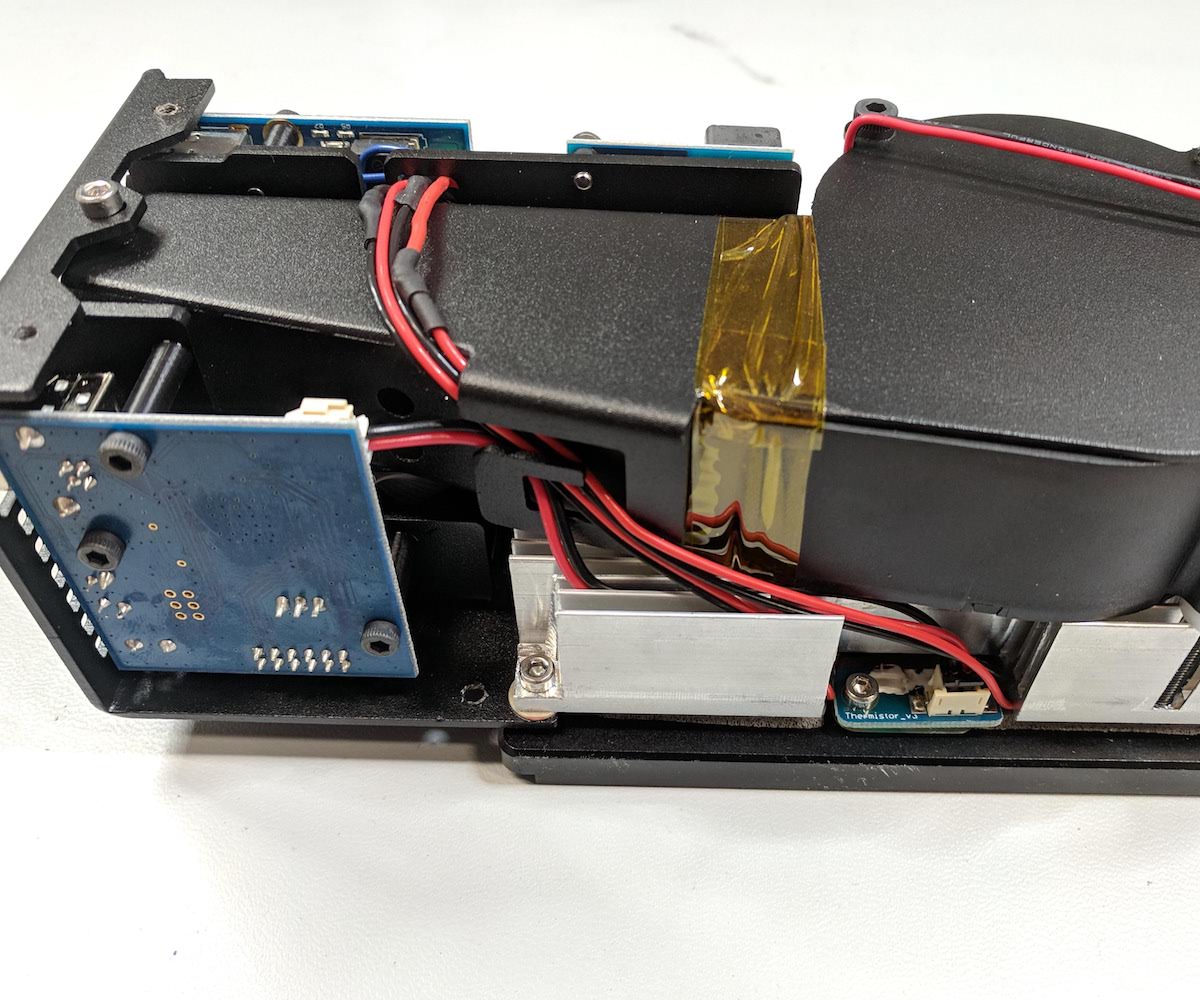

Thermocycler Module

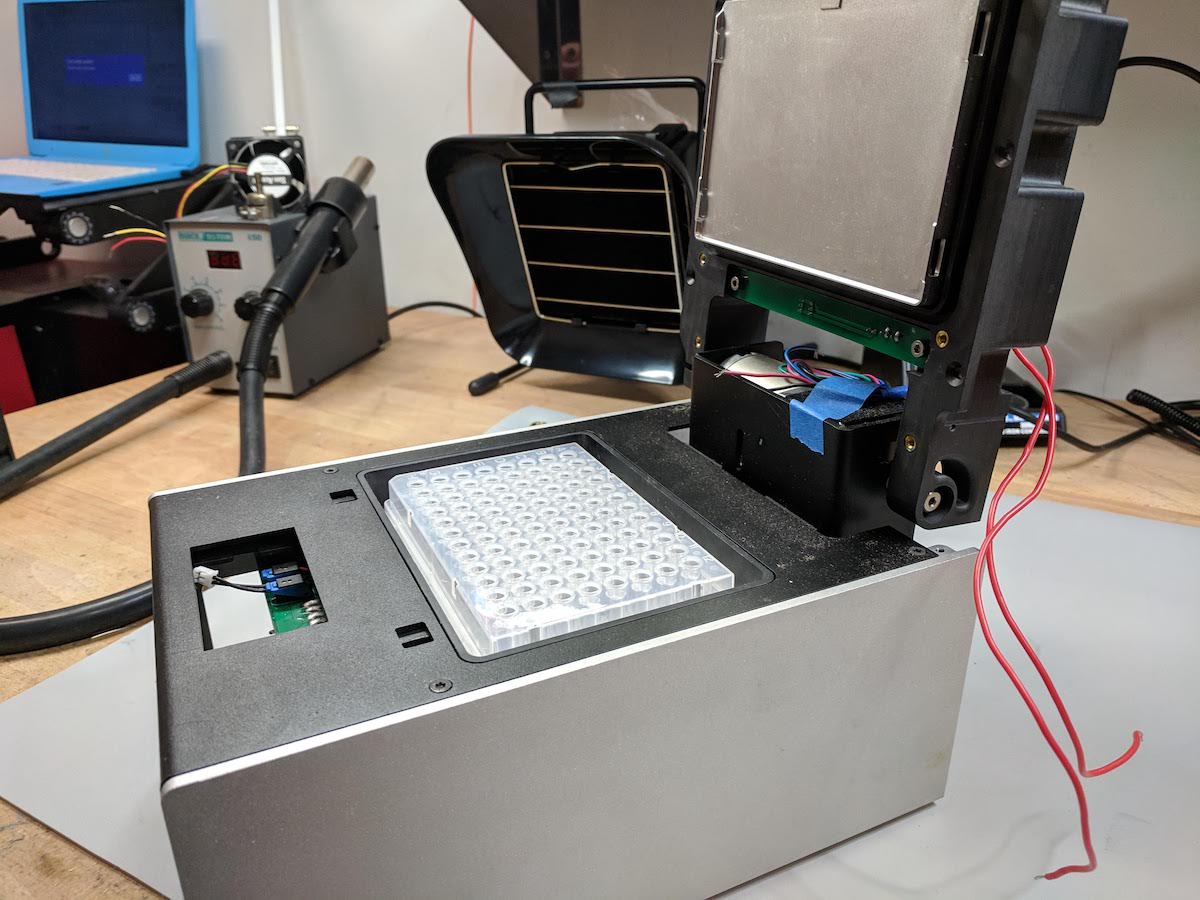

The Thermocycler ramps up and down in temperature, at about 4 degrees Celsius per-second, between 4-100 degrees Celsius.

The lid can automatically open/close. This lid is also used as a heating element, heating to 110-degrees Celsius.

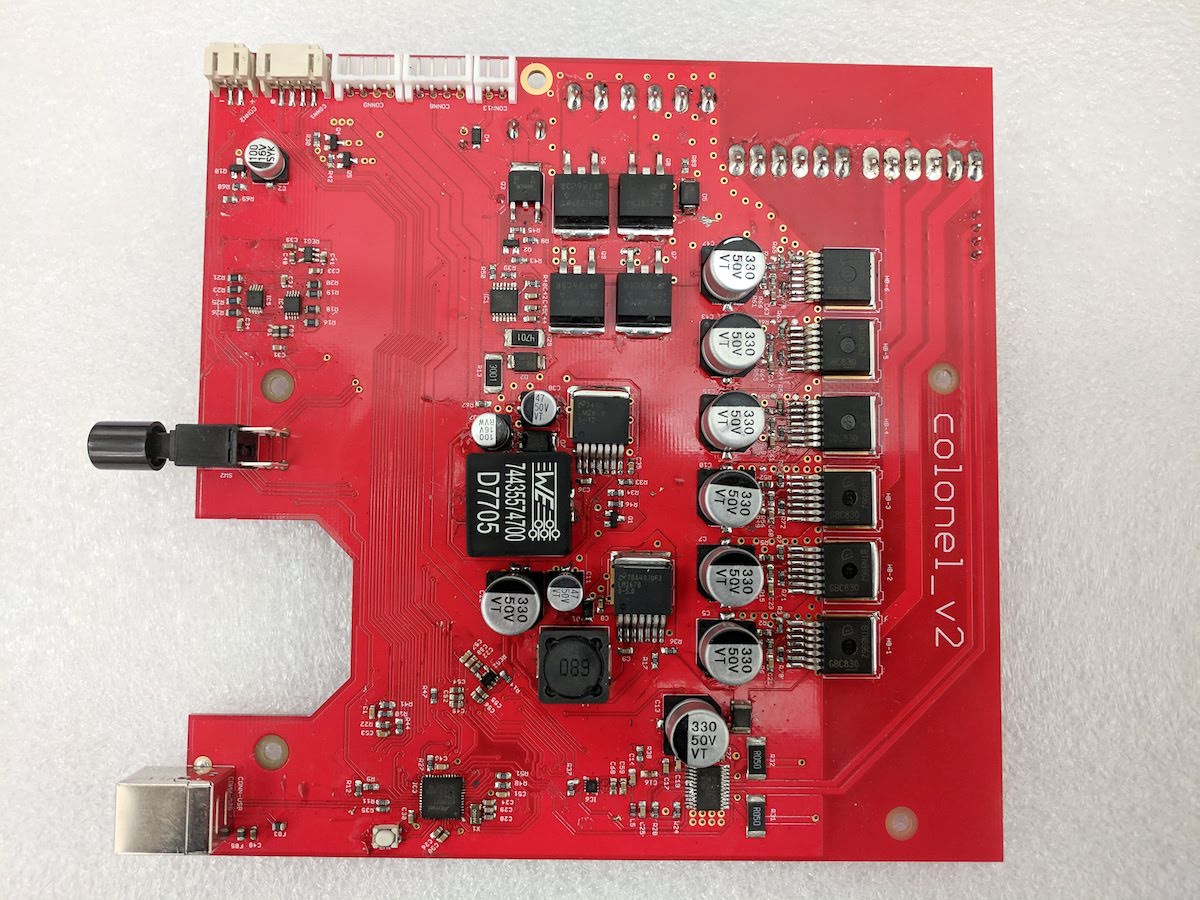

The main temperature control was driven by six peltier devices, driven separately to create a more uniform temperature gradient. In addition, the heated lid was driven by a heating pad, a stepper-motor driving system was needed to open/close the lid, and also a solenoid is used to latch the lid shut and pop it open.

Six separate thermistors are used to monitor the peltiers with an accuracy of <0.1 degrees Celsius. An RGBW LED strip was added as a basic status and progress indicator, and of course there is a power button on the side.

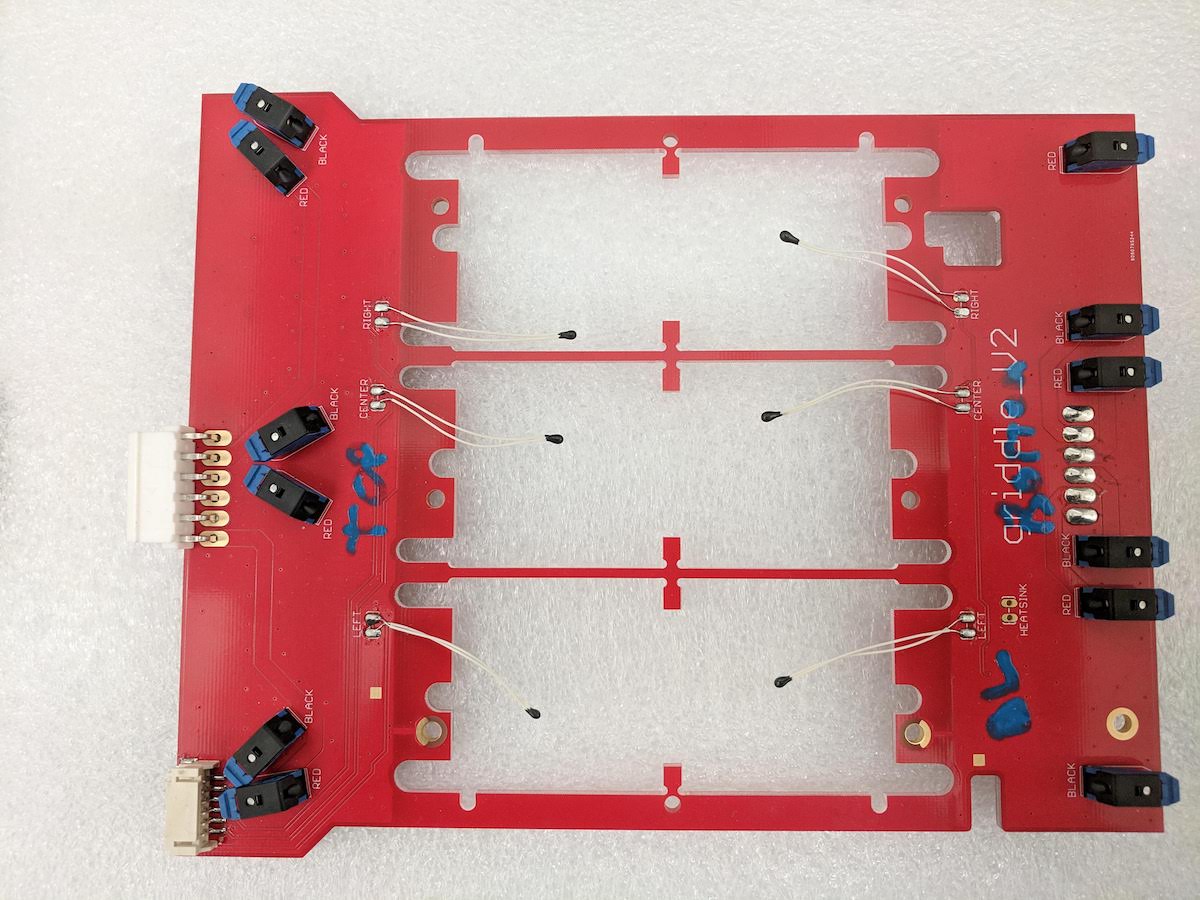

The PCBs pictured below were from the beta phase.

Below you can see about a dozen thermistors externally epoxied to the internal wells of an alpha prototype.

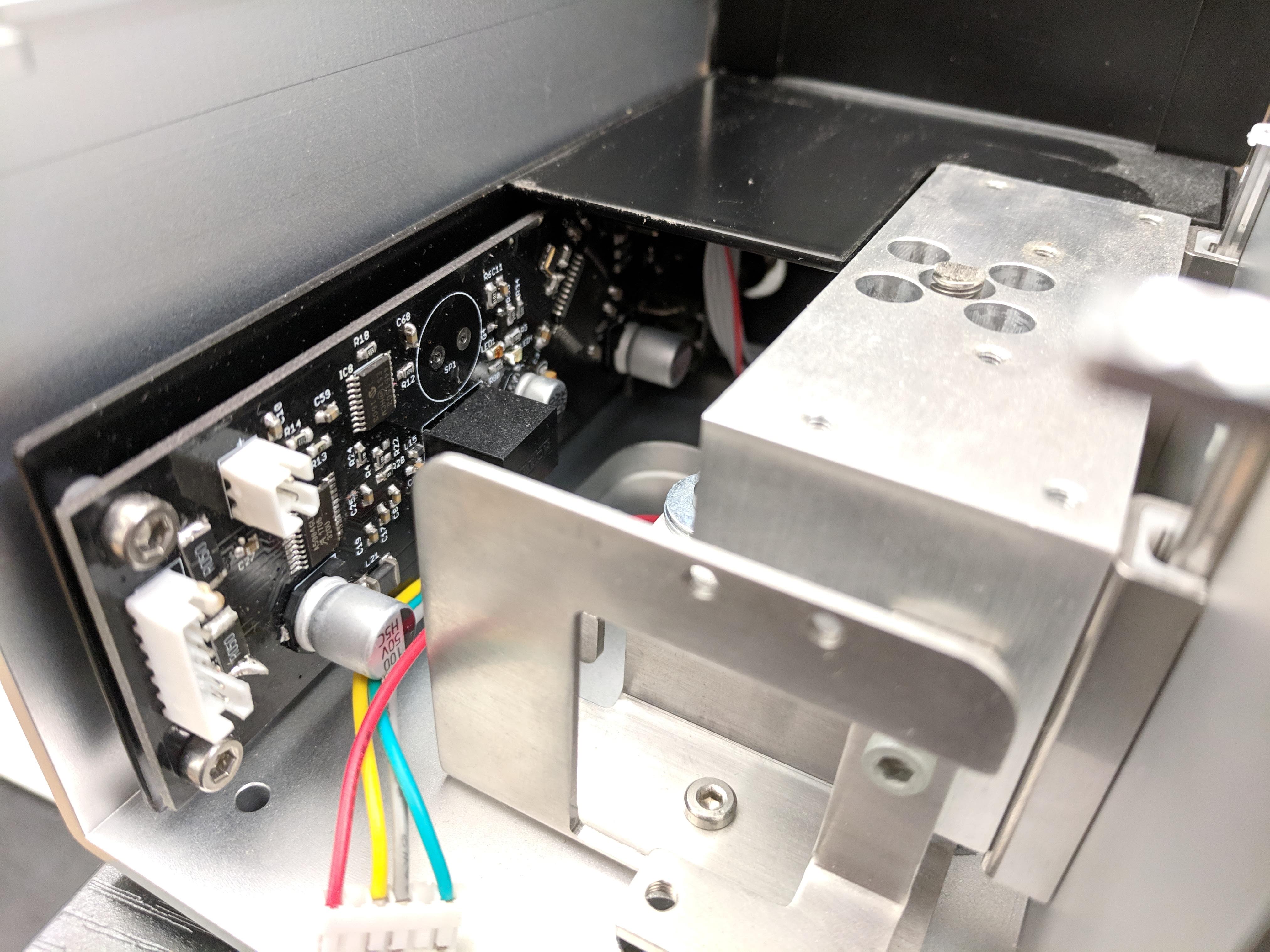

Temperature Module

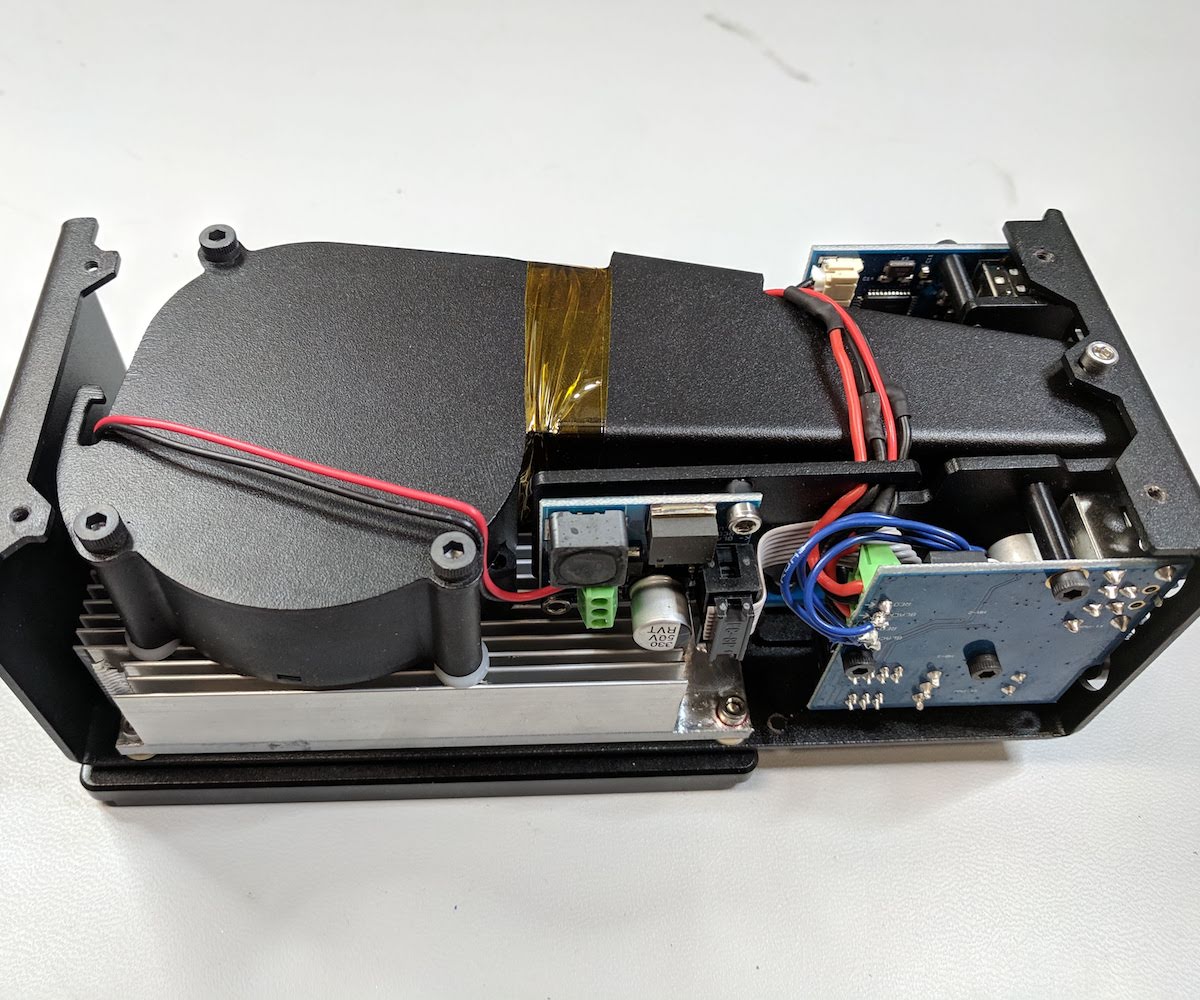

The Temperature Module can hold a temperature between 4-94 Celsius with +/- 1 Celcius accuracy and uniformity. Unlike the thermocycler (above), it was not designed to cycle between temperatures, but to instead hold a single steady temperature.

It uses two peltier devices to either heat or cool the top plate. A heatsink and fan are then used to cool the bottom side of the peltier devices. A display at the top of the device shows the current temperature, and red or blue colors to indicate temperature.

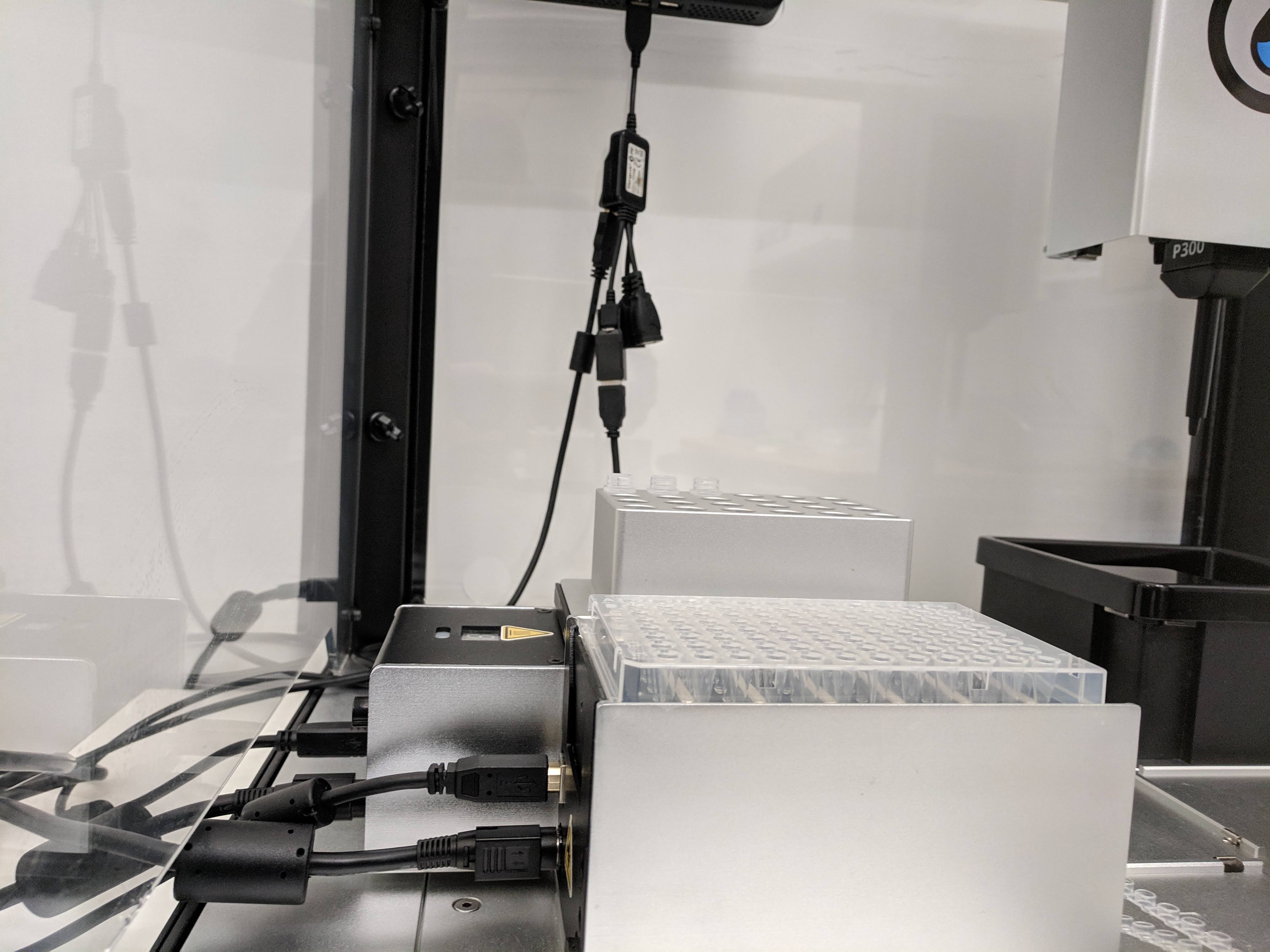

Magnetic Module

The Magnetic Module raises a set of magnets near the user’s sample, in order to attract iron beads that have been attached to a specific DNA strand to be isolated.

This device is composed of a stepper motor moving along a rail (to raise/lower the magnets), plus the electronics to move said motor.

PRODUCTS

opentrons pcb opensource